Liqui-Cel EXF Series

3M Liqui-Cel Membrane Contactors are commonly used for gas transfer with water or with fluids that have a similar surface tension to water. They utilize a patented radial flow design and are available in a variety of contactor sizes that are ideal for flow rates between 0,1-91 m<sup>3</sup>/h. Larger flow rates are easily handled by piping multiple contactors in parallel.

3M Liqui-Cel Membrane Contactors are commonly used for gas transfer with water or with fluids that have a similar surface tension to water. They utilize a patented radial flow design and are available in a variety of contactor sizes that are ideal for flow rates between 0,1-91 m3/h. Larger flow rates are easily handled by piping multiple contactors in parallel.

Capable of achieving < 1 ppm CO2 and < 1 ppb O2, Liqui-Cel Membrane Contactors provide significant benefits to industrial processes by removing or adding gases to liquids. Because of their cleanliness and predictability, LiquiCel Membrane Contactors are the standard degassing technology, installed in ultrapure water systems for the Semiconductor, Microelectronics and many other industries.

Although other degassing technologies, such as vacuum towers and forced draft deaerators exists for many years, these technologies may be displaced by LiquiCel Membrane Contactors. This is due to the smaller footprint, lower installation costs and the modular nature of membrane contactor systems. Contactors easily pipes together and can be readily expanded to meet growing capacity even after initial installation.

Benefits

- Modular design offers flexibility for meeting future capacity or tighten requirements;

- High inlet pressure and low pressure drop reduces the need for repressurization pumps;

- Maximised surface area/volume results in high performance and space efficiency;

- No chemicals required to operate the membrane contactor;

- Fast equilibrium means quick start-ups;

- Different contactor sizes and material options provide tremendous flexibility;

- Non-dispersive characteristics allow the contactor to be operated over a wide range of flow rates;

- Simple operation could reduce instrumentation and maintenance requirements.

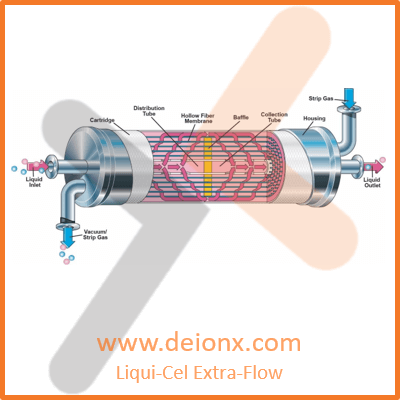

Contactor Design

The Extra Flow design uses a central baffle to force liquids radially over the fiber array. Liquid flows on the outside (shell side) of the hollow fibers.

The High Pressure design is similar to the Extra-Flow with center baffle design, but with a different housing concept (RO style vessel) for high pressure applications. 8 x 40 and 8 x 80-inch use this design.

Applications

LiquiCel Membrane Contactors can be used in a wide range of applications. DeionX focuses on using them for removal of CO2 and O2 in ulta pure water applications for:

- Semiconductor/ Microelectronics Industry

- Pharmaceutical Industry

- Power Generation

Downloads

- Liqui-Cel-EXF-8×80-Membrane-Contactor

- Liqui-Cel-EXF-10×28-Industrial-Membrane-Contactor

- Liqui-Cel-EXF-10×28-Membrane-Contactor

- Liqui-Cel-EXF-14×28-Membrane-Contactor

- Liqui-Cel-EXF-2.5×8-Membrane-Contactor

- Liqui-Cel-EXF-4×13-Membrane-Contactor

- Liqui-Cel-EXF-6×28-Membrane-Contactor

- Liqui-Cel-EXF-8×20-Industrial-Membrane-Contactor

- Liqui-Cel-EXF-8×20-Membrane-Contactor

- Liqui-Cel-EXF-8×40-and-EXF-8×80-Cartridge-Membrane-Contactor

- Liqui-Cel-EXF-8×40-Membrane-Contactor