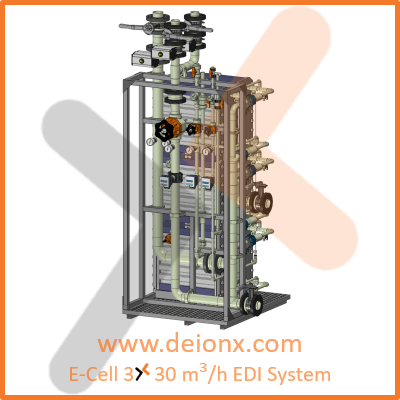

Specifications

| Stack Specifications |

|

MK-3 |

| Nominal flow |

3,4 m³/h |

| Maximum flow |

1,7 to 4,5 m³/h |

| Shipping weight, approx. |

92 kg |

| Dimensions (w x h x d), approx. |

31 x 61 x 48 cm |

| Typical Performance |

| Resistivity |

>16 MOhm·cm |

| Sodium |

< 3 ppb |

| Silica (SiO2) Removal |

Up to 99% or < 5 ppb |

| Boron Removal |

> 95 % |

| Operating Parameters |

| Recovery |

Up to 97 % |

| 1Concentrate flow |

Counter current to Product flow |

| Voltage |

0 – 300 VDC |

0 to 400 VDC |

| Amperage |

0 to 5,2 ADC |

| Inlet Pressure (Counter Current) |

4,1-6,9 bar |

| Inlet Pressure (Co-Current) |

3,1-6,9 bar |

| Pressure Drop at Nominal Flow |

1,4-2,8 bar |

| Maximum Feedwater Specifications |

| Feedwater – Total Exchangeable Anions (TEA as CaCO3) |

< 25 mg/l |

| Feedwater – Conductivity, NaHCO3 equivalent |

< 43 µS/cm |

| Temperature |

5 to 40 ⁰C |

| Total hardness (as CaCO3) |

< 1.0 mg/l |

| Silica (SiO2) |

< 1.0 mg/l |

| Total Organic Carbon, TOC as C |

< 0.5 mg/l |

| Total Chlorine |

Total Chlorine < 0.05 mg/l |

1Co-flow operation is acceptable when feed hardness

concentrations are <0.1 ppm as CaCO3.